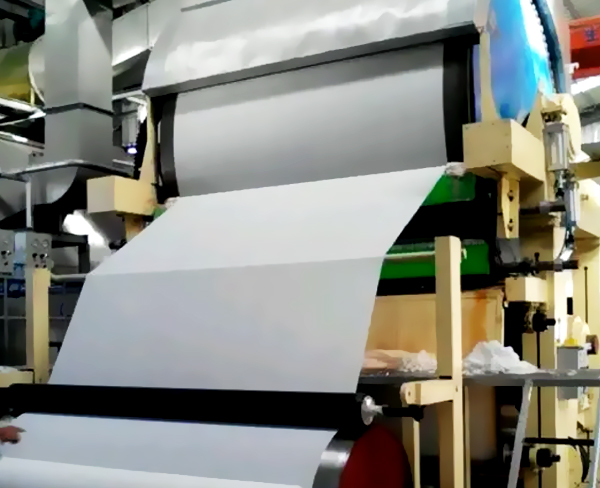

Application scenarios

Video presentation

Product introduction

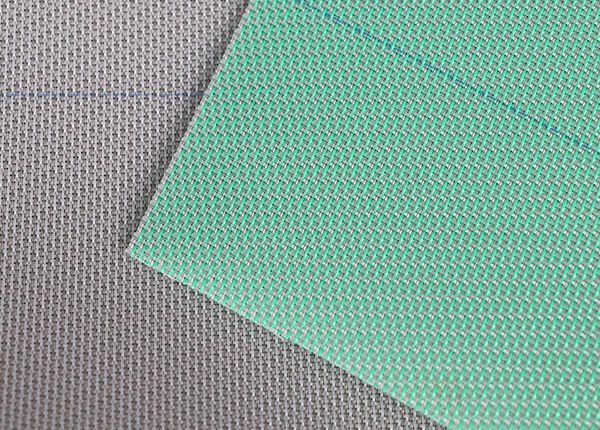

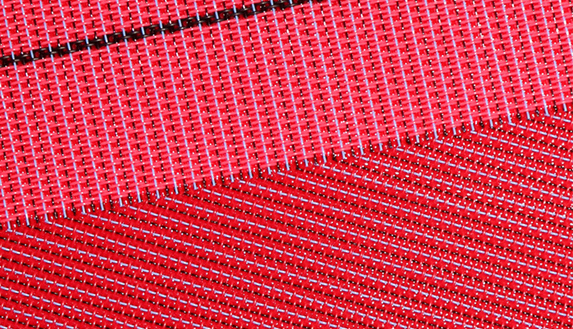

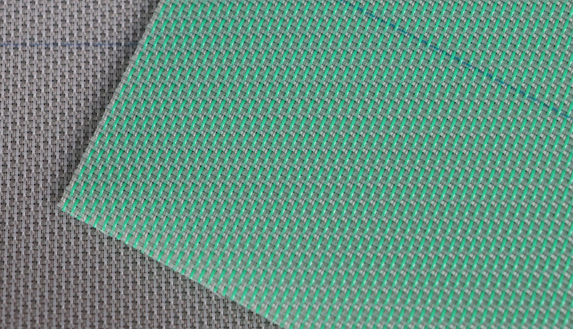

Paper feltrefers to the fabric felt used for paper forming and conveying in the paper industry.

According to the position on the paper machine, it can be divided into wet felt, upper felt and dry felt.

Paper felts require good dehydration, smoothness, dirt resistance, abrasion resistance, dimensional stability, chemical resistance, antibacterial resistance, heat resistance and hydrolysis resistance, etc.

According to the position on the paper machine, it can be divided into wet felt, upper felt and dry felt. The wet felt runs with water on the paper machine, and its function is to press the blank to dewater and smooth the surface of the paper. The wet blanket has good water filtration and elasticity, high strength, small shrinkage, wear resistance, anti-bacteria and acid-base corrosion resistance.

Product advantages

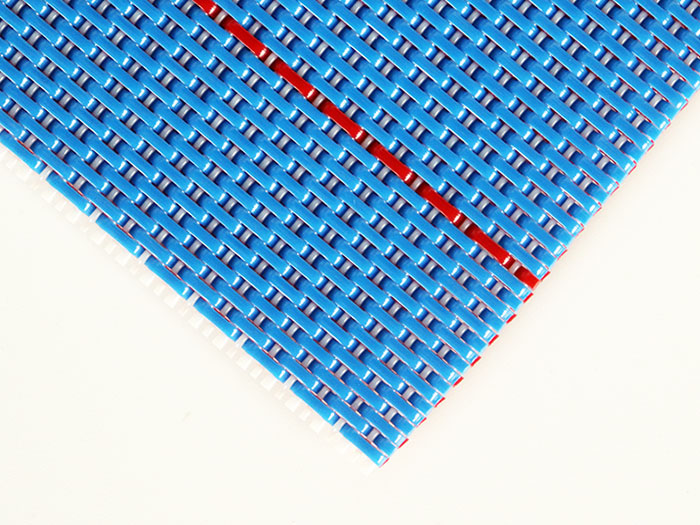

Stable heat setting

Stable heat setting

No quality problems of ruffles, bell mouths, loose and tight at the same time, not be turned during production.

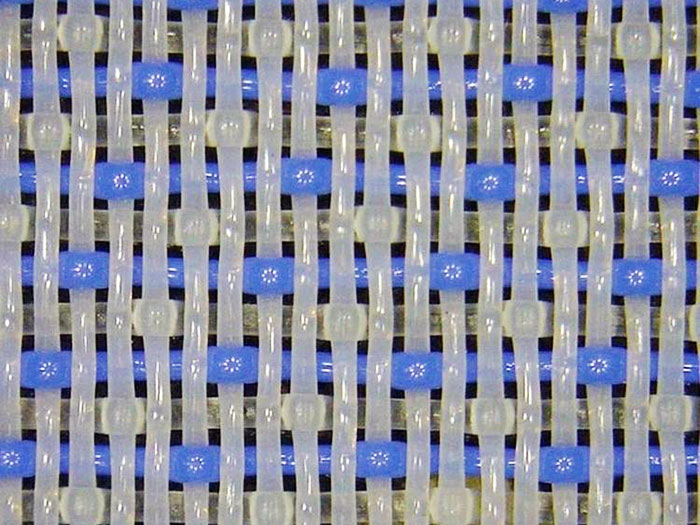

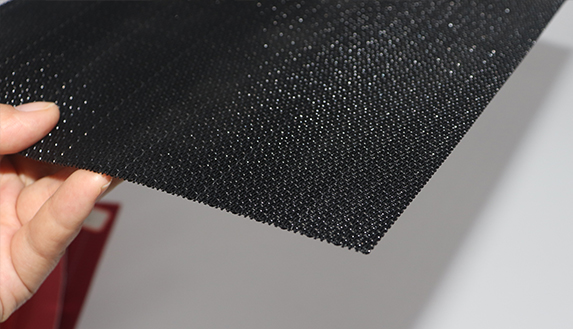

Flat wire filler

Flat wire filler

Square the loop more space, so not easy to move, more stable performance.

Stable heat setting

Stable heat setting

No quality problems of ruffles, bell mouths, loose and tight at the same time, not be turned during production.

Flat wire filler

Flat wire filler

Square the loop more space, so not easy to move, more stable performance.

English

English 中文

中文 Russian

Russian Spanish

Spanish Arabic

Arabic German

German