Polyester mesh is made of PET material, and its strength is several times that of woven dry blanket, canvas, nylon and general plastic mesh. In addition, it has the advantages of good air permeability and high heat transfer efficiency, which can save energy for users, and is easy to install and use. It is widely used in non-woven fabric manufacturing, papermaking, environmental protection filtration, food, printing, coal washing and other industries.

According to different weaving methods and usage scenarios, polyester mesh belt can be generally divided into: non-woven mesh belt, polyester spiral mesh, square hole plain mesh, herringbone sludge dewatering mesh, spiral pressure filter mesh, paper forming mesh, Electrostatic net, desulfurization net, etc.

Non-woven mesh belt: The industry term is called "net curtain", which is widely used in non-woven non-woven equipment, and its main function is to form and convey polypropylene non-woven fabrics. According to different weaving methods and materials, it can be divided into round wire mesh belt, flat wire mesh belt, anti-static mesh belt, anti-hydrolysis mesh belt, etc.

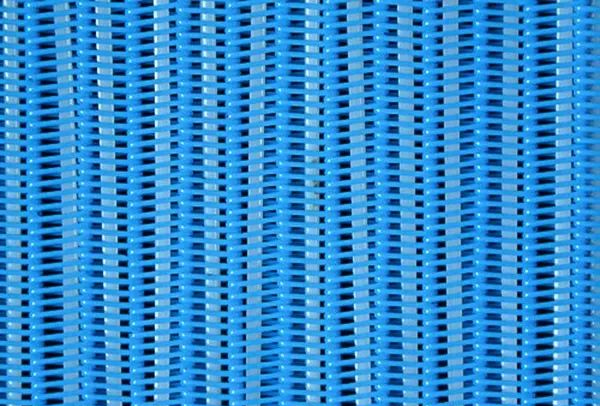

Polyester spiral mesh: It has the advantages of high air permeability, flat mesh surface, arbitrary disassembly, good strength and long service life. The special material spiral dryer also has the characteristics of high temperature resistance, high wear resistance and aging resistance. It is widely used in meltblown nonwovens, papermaking, coal mines, food, medicine, printing and dyeing and rubber products industries.

Paper forming wire: It is an important equipment on the paper machine, and it is a device for sheet forming and dewatering on the paper machine. It dewaters the pulp suspension from the headbox and runs the paper web to the subsequent section. The forming net has various types and classification methods, and is generally classified according to the number of layers and the number of healds.

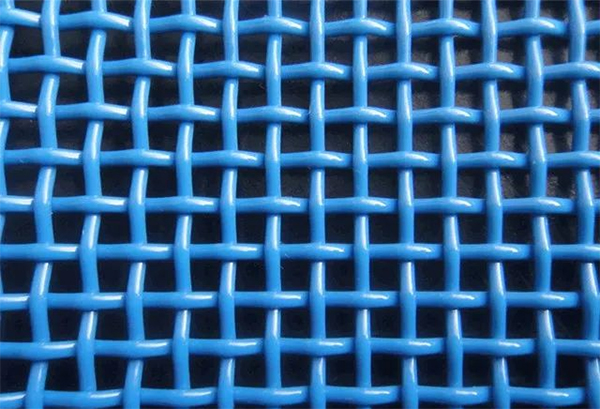

Square hole plain weave mesh: It has the characteristics of non-toxic, no peculiar smell, smooth surface, anti-sticking material, corrosion resistance, good bending performance, wear resistance, high tensile strength and easy cleaning. Mainly used in non-woven fabric manufacturing, wood-based panel plant paving machine, fruit and vegetable conveying and drying, sludge dewatering machine, material screening, environmental protection and other industries. The general classification method is to classify according to the density and the number of meshes, and the unit is "mesh".

Spiral press filter: The screw press filter is to add filler wire into the spiral ring to reduce the air permeability and reduce the loss of material on the mesh surface. It is mainly used for the press filter belt of belt dehydrator, papermaking, printing and dyeing, food , chemical industry, alcohol, vinegar industry, coal washing, mining, papermaking and pulp washing, pharmaceutical, sludge dewatering, ceramic industry and sludge dewatering and other solid-liquid separation industries.

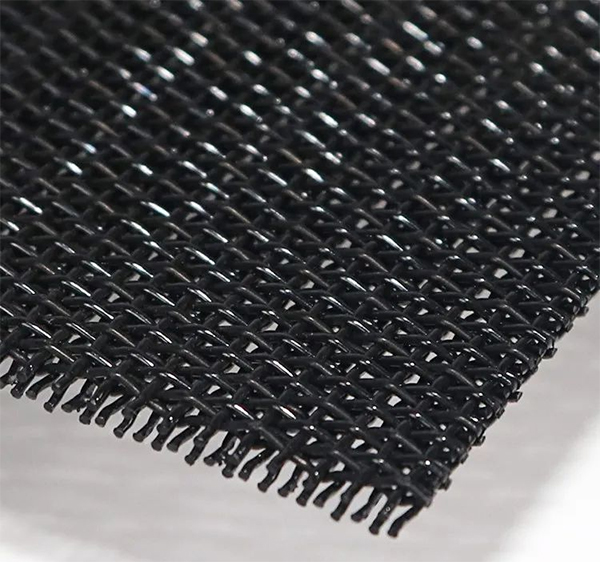

Anti-static mesh: The equipment using polyester mesh will generate static electricity when it is running at high speed. The conductive fiber monofilament is pierced through the polyester mesh, which can release the static electricity and play an anti-static effect. Mainly used in non-woven fabric manufacturing, environmental protection, high density board production, rubber, chemical fiber, dry papermaking, fiberboard continuous press mesh belt, continuous pre-press machine mesh belt and materials that require conductive and antistatic industries.

Henan Yiheng Mesh Co., Ltd. is a professional polyester mesh manufacturer with advanced technology and rich production experience, focusing on the research and development, production and sales of polyester mesh belts, with nearly 19 years of industry experience. The maximum speed of polyester mesh belt produced by YIHENG can reach 1100 meters/min, the maximum size is over 9x100 meters, and the maximum air permeability can reach 12000±500.

English

English 中文

中文 Russian

Russian Spanish

Spanish Arabic

Arabic German

German