Application scenarios

Product introduction

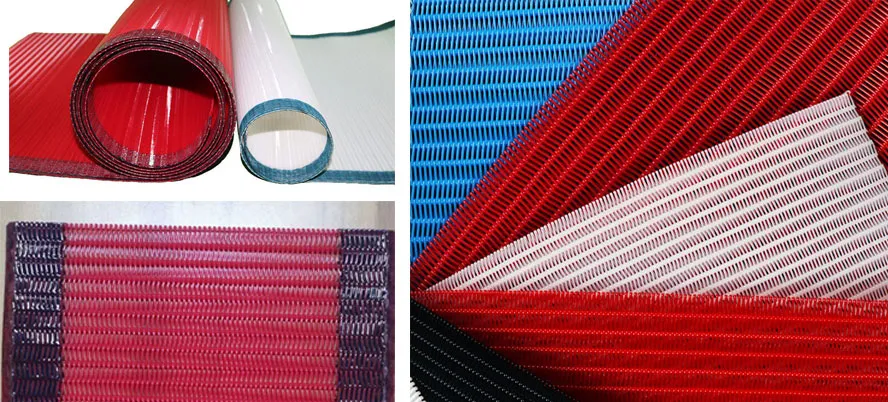

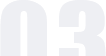

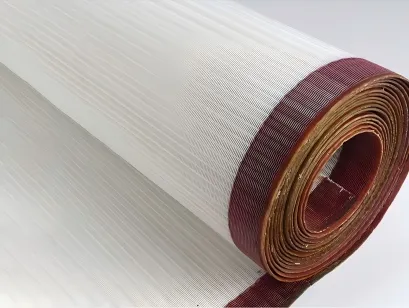

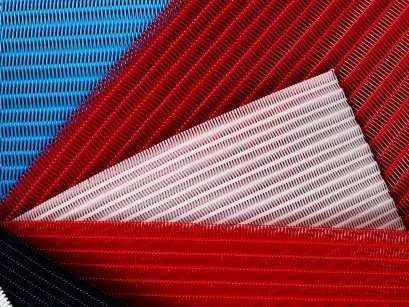

Filter Press Belt is suitable for the production of melt-blown non-woven fabrics, drying packaging paper, cultural paper cardboard and pulp board with large quantification.

Widely used in papermaking, coal mining, food, medicine, printing and dyeing and rubber products industries, suitable for horizontal belt vacuum pulp washer bottom mesh (replacement of rubber belt), can also be used as conveyor belt and laminating machine matching mesh belt.

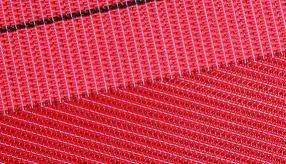

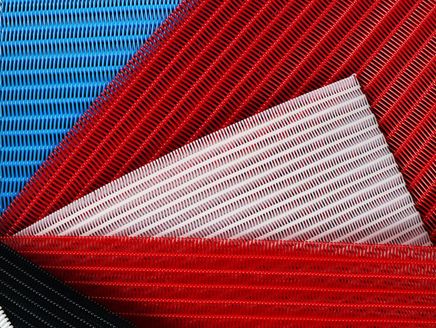

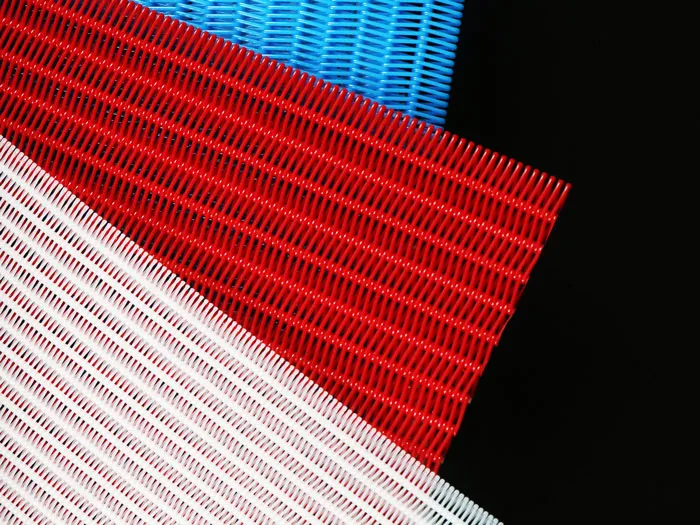

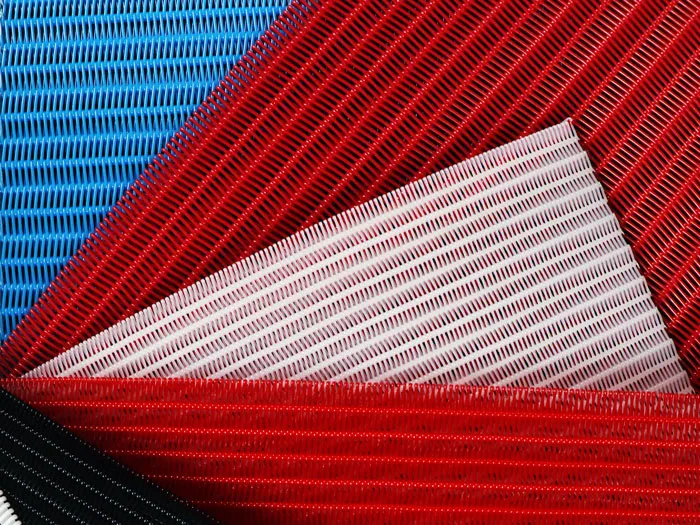

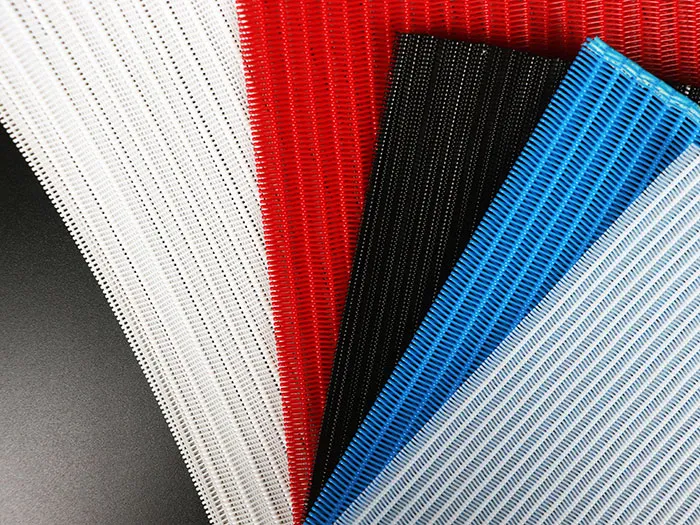

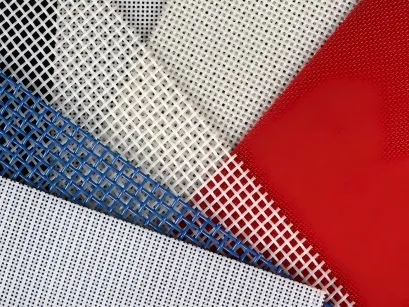

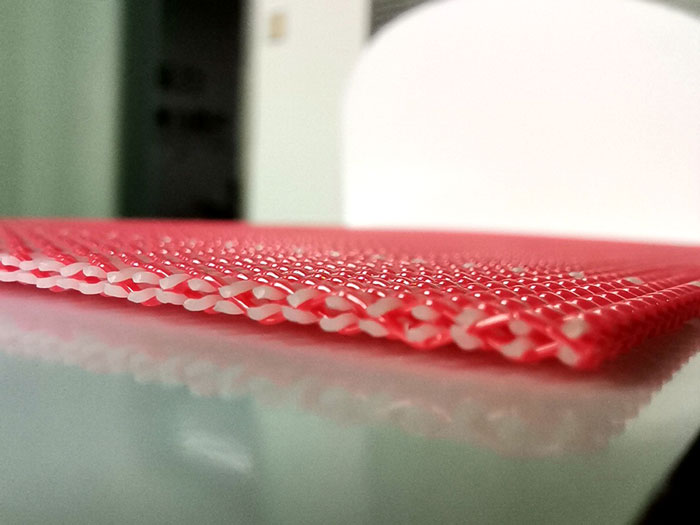

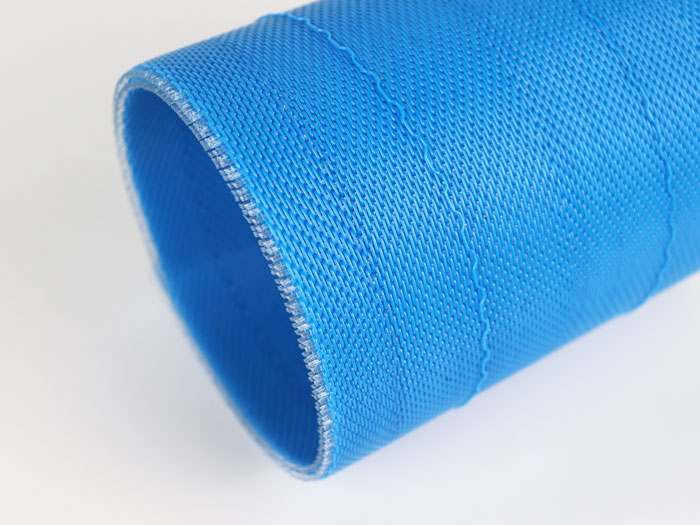

Polyester spiral dry mesh has the advantages of high air permeability, flat mesh surface, arbitrary disassembly, good strength and long service life. The special material spiral dryer also has the characteristics of high temperature resistance, high wear resistance and aging resistance.

The press filter mesh is to add filler wire into the spiral ring to reduce the air permeability and reduce the material loss on the mesh surface. Vinegar industry, coal washing, mining, papermaking and pulp washing, pharmaceuticals, sludge dewatering, ceramic industry and sludge dewatering and other solid-liquid separation industries.

Product advantages

large air-permeability

large air-permeability

Wear-resistance, high-temperature resistance, aging-resistance

Wear-resistance, high-temperature resistance, aging-resistance

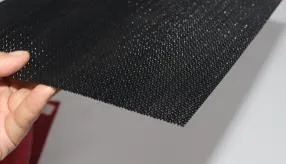

Can be disassembled at will

Can be disassembled at will

English

English 中文

中文 Russian

Russian Spanish

Spanish Arabic

Arabic German

German

fillers can be filled according to customer requirements

fillers can be filled according to customer requirements