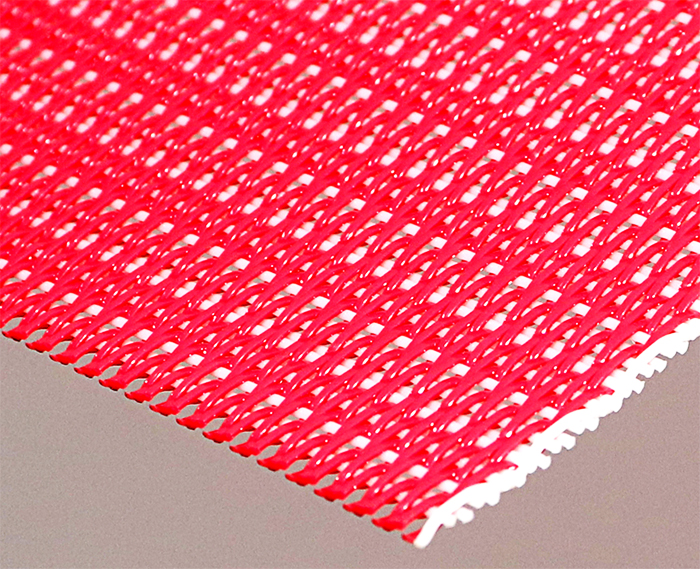

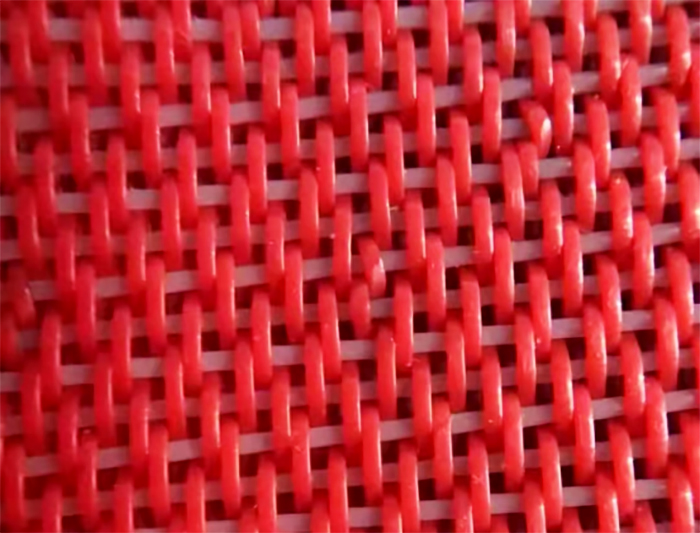

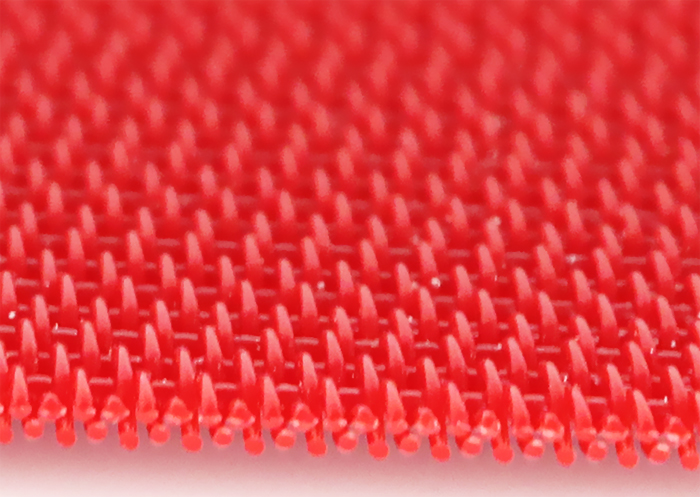

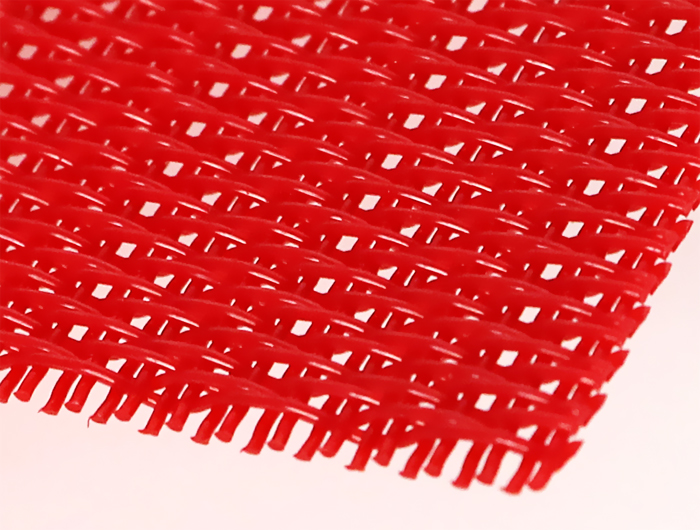

One of Turkey customers contact me for mesh belts, after i quote him, he said it higher than the belt he buy and later he share the photo of belt he now use with me,from the photo,we can note that its weaving structure are not same. In our industry, we know if weaving structure is designed ok, it should be same. Why different? It because the weaving machine is too old and programming has problem. To save cost,some belts supplier not buy new machine, it attract many customers, but most customers do not know why their fabric quality not good after use the cheap belt. Here we should know that belt’s air permeability uniformity will affect nonwoven fabric uniformity, if weaving structure is not same, air permeability will be not uniform, then nonwoven fabric will not good. After i explain to this customer, he said he has such problem and try to buy some belts from us. After use, he said very good.

Henan Yiheng Mesh Co., Ltd. is a professional polyester mesh manufacturer with advanced technology and rich production experience, focusing on the research and development, production and sales of polyester mesh belts, with nearly 19 years of industry experience. The maximum speed of polyester mesh belt produced by YIHENG can reach 1100 meters/min, the maximum size is over 9x100 meters, and the maximum air permeability can reach 12000±500.

English

English 中文

中文 Russian

Russian Spanish

Spanish Arabic

Arabic German

German