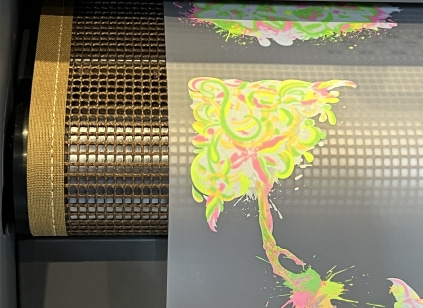

Application in UV mesh belt machine

UV Conveyor Belt Features

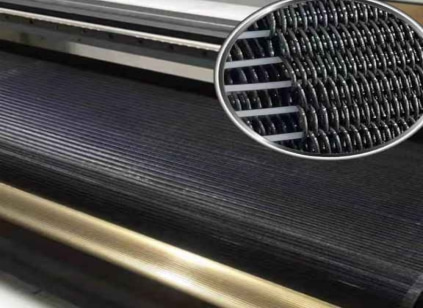

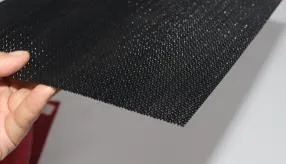

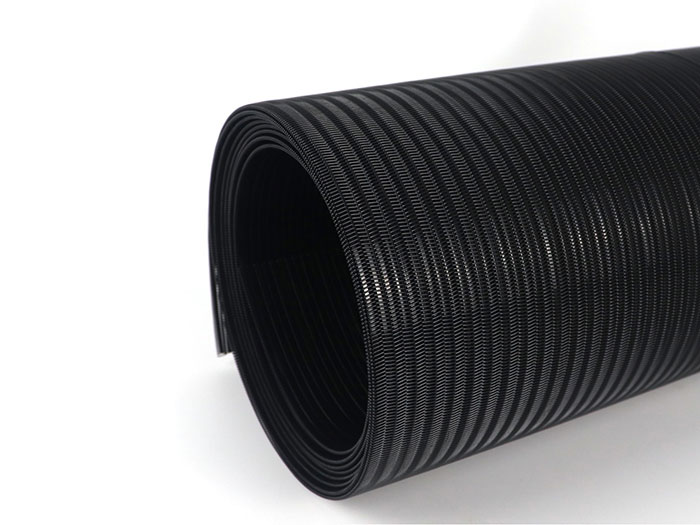

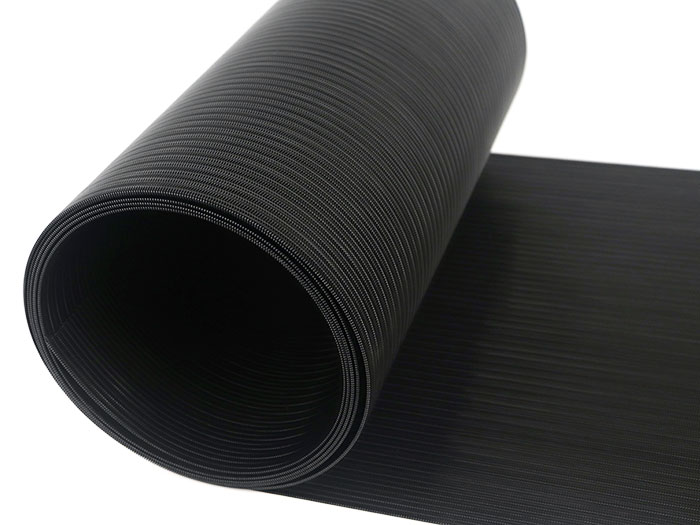

The UV digital printer conveyor belt is specially designed for UV curing machines and wide format digital printers. It is made of high viscosity black polyester monofilaments in a spiral loop structure, woven with advanced warp and weft technology. This ensures uniform density, excellent tensile strength, and a smooth surface without burrs or broken wires.

Advantages of Polyester Mesh Belt for UV Conveyor Machine

1.High temperature resistance, stable under UV curing conditions

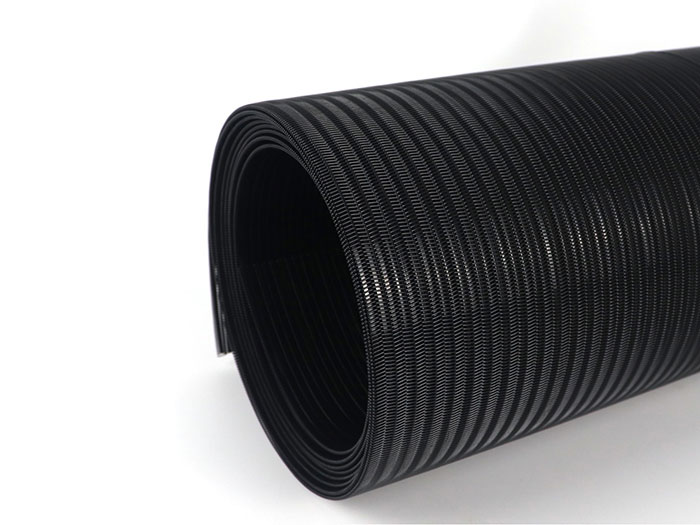

2.Strong tensile strength and long service life

3.Uniform mesh density, smooth running without deformation

4.Good air permeability and light transmittance for effective UV curing

5.Easy to clean, non-stick surface, low maintenance

6.Reinforced edges, easy installation and repair

7.Widely used in UV printers, UV curing systems, and screen printing dryers

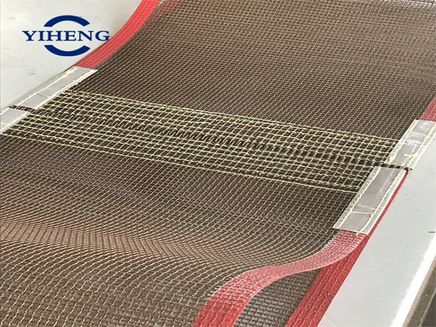

Durable Edge Design

1.The conveyor belt is reinforced with widened latex sealing edges. This makes it soft, lightweight, and resistant to peeling, ensuring a long service life.

Applications

1.Thanks to these advantages, UV conveyor belts are widely used in UV digital printers, UV curing conveyor systems, and wide-format hybrid roll-to-roll printers.

UV Conveyor Belt Features

Stable quality

Stable quality

No quality problems of ruffles, bell mouths, loose and tight at the same time, not be turned during production.

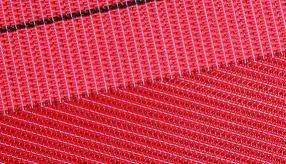

Uniform density

Uniform density

Square the loop more space, so not easy to move, more stable performance.

Smooth mesh surface

Smooth mesh surface

No quality problems of ruffles, bell mouths, loose and tight at the same time, not be turned during production.

Wear resistance, high temperature resistance

Wear resistance, high temperature resistance

Square the loop more space, so not easy to move, more stable performance.

English

English 中文

中文 Russian

Russian Spanish

Spanish Arabic

Arabic German

German